TRANSPARENT ARMOR PRODUCTS

Standard Bent Glass Corp has been well known in the custom glass industry since 1936, as well as the industry leader in custom glass bending. Today SBG offers a complete line of innovative solutions for Transparent Armor Vehicle OEM’s and Direct USG customers. Our 180,000 square foot facility is fully equipped with state-of-the-art manufacturing capabilities for glass laminating.

Technical Specifications

- ATPD 2352 – Multiple Threat Levels Approved

- Environmental First Article/PLT

- Ballistics First Article/PLT

- STANAG 4569

Transparent Armor Platforms Approved on

- LTV

- FMTV

- HTV

- STRYKER

- MRAP

- AMS

- HIMARS

- EBFL

- CE

Technical Capabilities

- All in house fabricating of glass – cutting, edging

- Tempering

- In House De-Ice Capabilities

- Bending

- Frit

- Mil Spec Labels

- Comply with Mil Spec Customized Packaging

- Warranties – Offer Extended Warranties

- R & D

- Engineering

- Reverse Engineering

- Frame Design

- Deliver complete Transparent Armor Assemblies

- Single sourced state of the art 180,000 sq ft manufacturing facility

- Three (3) Auto-Claves for material bonding and lamination

- Four (4) laminating lines

- Proprietary technology for Heated Wind-Shields

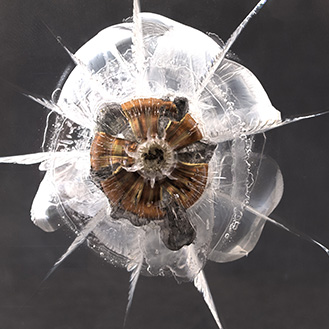

- ROCKSTRIKE™ Transparent Armorfor resistance to breakage

- DLCscratch resistant glazing

- Personnel with Secret Clearance